Steel Manufacturing

Our Steel Manufacturing workshop showcases our commitment to excellence with cutting-edge laser and punching machines that enhance precision and efficiency. By utilizing the latest technologies in bending machines, we deliver high-quality steel components that not only meet but exceed the rigorous standards of our clients.

Tank Welding

Our Tank Welding workshop reflects our dedication to responsibility through stringent safety measures and quality controls. Equipped with specialized fin folding machines, MIG and TIG welding machines, and a leak testing chamber, all operated by well trained and certified welders to ensure the integrity and durability of our welded tanks.

Surface Treatment & Painting

Our Surface Treatment and Painting workshop integrates excellence and innovation with a state-of-the-art grit blasting chamber and automated chemical spraying tunnels for optimal surface preparation. We employ advanced electrostatic and liquid painting techniques to create high quality, durable coatings that enhance both the aesthetic and protective qualities of our products, ensuring they endure rigorous operational environments.

Winding

The Winding workshop features state-of-the-art aluminum and copper foil and wire winding machines. With advanced flattening units designed for eco-friendly transformers, we produce efficient solutions that minimize environmental impact while maintaining the highest standards of performance.

Magnetic Core

In the Magnetic Core workshop, we prioritize innovation by leveraging advanced technologies for core cutting and stacking. This allows us to manufacture magnetic cores with exceptional precision, serving a diverse range of applications in the electrical and electronics industries, while ensuring reliability in every production process.

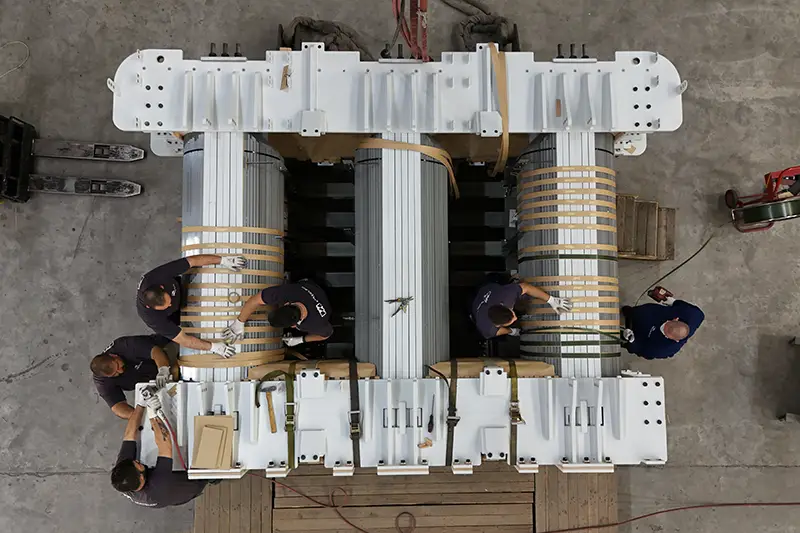

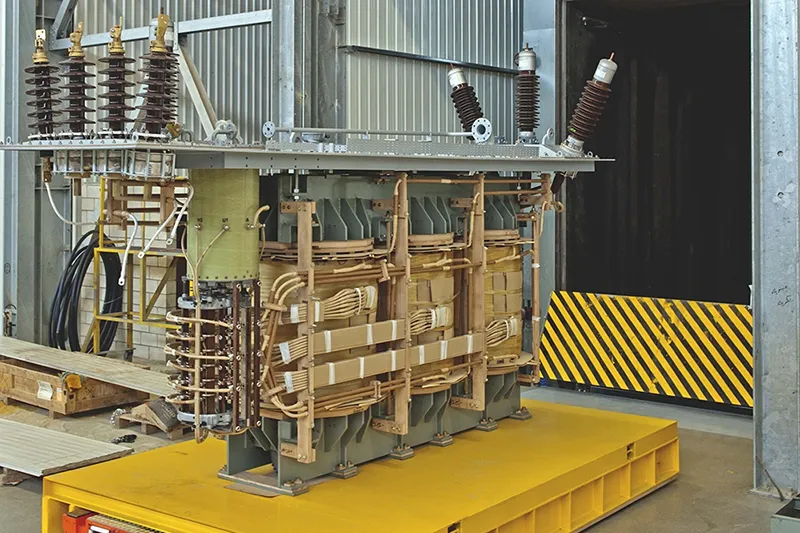

Active Part Assembly & Drying

In our Active Part Assembly and Drying workshop, we emphasize agility and responsibility by utilizing a Transformer Vacuum Drying Plant and a Vapor Phase Drying Plant for precise drying processes. This enhances transformer performance and longevity, while our oil filling under vacuum ensures optimal conditions and reduces contamination risks.

Our manufacturing workshops operate under rigorously certified quality management systems, ensuring that every product meets our superior standards. Our production processes are safeguarded by comprehensive Quality Control Plans (QCPs), meticulously designed to detect any potential defects stemming from engineering or manufacturing flaws. To ensure optimal performance,

QCPs are implemented at every stage of production, from testing raw materials and purchased components at the supplier’s premises or during receiving inspection, conducting in-process inspections and tests to verify conformity to design to performing thorough final inspections and tests on end products. All final tests adhere to international standards.

For us, quality and reliability are at the core of our production process, ensuring that every product meets the highest standards.

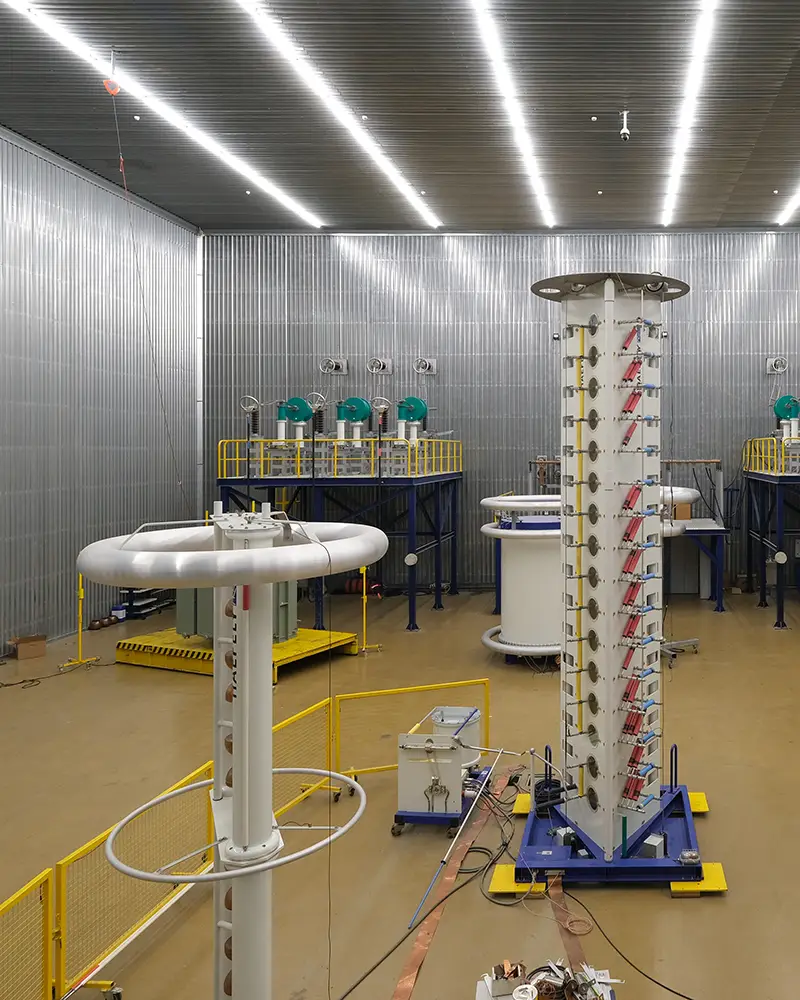

Each transformer undergoes rigorous final inspection and testing in our specialized high-voltage and medium-voltage test bays. Our comprehensive testing process includes routine, dielectric, and temperature rise tests, as well as specialized evaluations such as capacitance determination, transient voltage transfer characteristics, insulation resistance, sound level measurement, and partial discharge analysis. Additionally, insulating liquid analysis is conducted on-site, while short-circuit tests are performed in internationally accredited laboratories.

Similarly, our MV/LV products undergo strict quality control measures before dispatch. Our highly experienced testing team, equipped with the latest technology, performs dielectric routine tests, resistance measurements, mechanical operation tests, and thorough inspections of auxiliary and control circuits, ensuring optimal performance and safety.

Designed to withstand over 20 years of operation in demanding outdoor environments, our products receive first-class corrosion protection.

We prioritize safety above all, and believe that all accidents and injuries are preventable. A strong safety-first mindset is embedded in our daily operations, fostering a proactive and engaged workforce. Our ISO 45001 certification reflects our dedication but every individual, from leadership to frontline workers, shares responsibility for maintaining the highest safety standards. By regularly reviewing procedures, integrating the latest safety technologies, and engaging employees in safety initiatives, we remain committed to protecting our people.